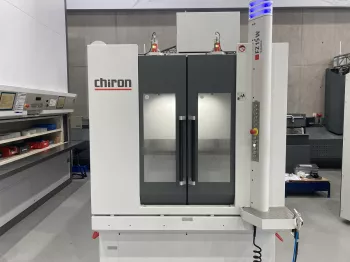

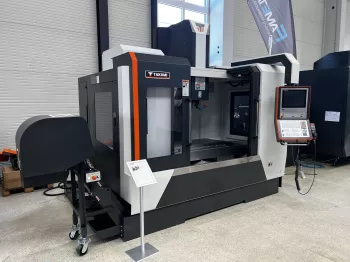

CNC milling machines: Demonstration machines & machines from discontinued model ranges – top-notch machining with excellent value for money

Milling machines as demonstration models or from discontinued model ranges score points over brand-new machines because they offer excellent value for money and boost competitiveness owing to their low unit costs. At the CNC Outlet Center near Munich we offer a large range of top-class milling machines for industry or trade use – in different price categories and from renowned manufacturers.

The range of milling machines on offer extends from simple 3-axis milling machines and universal 5-axis centres through to high-performance machining centres for large-scale production. Our team of experienced application technicians will give you a live demonstration of the milling machines on site and advise you on suitable areas of application.

Contact us to arrange an appointment or just pop by to visit.

Benefits of milling machines from the CNC Outlet Center

Here is an overview of the benefits of purchasing a demonstration or used machine from the CNC Outlet Center:

- Lower purchasing costs

- Lower depreciation compared to a new purchase

- Rapid amortisation

- Short lead times and rapid availability

- All machines set up for live demonstration

- Expert advice right on site

- Special rates on accessories such as tool holders or clamping devices

- Individual services in relation to financing or installation

Large selection of milling machines – our machine tool brands

At the CNC Outlet Center you will find milling machines of all technologies and brands, including horizontal milling machines, vertical machining centres and universal milling machines from various manufacturers.

Our selling point: Individual services for your CNC milling machine

At the CNC Outlet Center we offer you individual advice in person. In addition, we offer you comprehensive services such as financing, part exchange of used machines, logistics services, commissioning and training as well as valuations of your machines or your entire company.

We can adapt all service terms to suit your ideas and budget. If you have any questions about our range of services, feel free to contact us at any time.